The subject of this book review is perhaps a little outside my usual scope, being a history of largely mechanical engineering developments. The book is ” The Secret Horsepower Race: Western Front Fighter Engine Development” by Calum Douglas.

Is there a more complex piece of machinery in history than a WW2 fighter engine combining dozens of technologies- with demands on it from 0, to 35,000 feet, and when life or death is the outcome?

This book has sparked significant interest from me for a number of reasons:

- I’m originally a metallurgist and there’s a fair bit of that in there.

- I have some background in Technical Intelligence matters in a previous life, decades ago, and there was plenty of that going on in the 1930’s and 1940s in this field. Techniques were largely the same!

- Although I’m not a mechanical engineer I have a modicum of knowledge and recently have been refurbishing a 1914 stationary engine – this gives me just enough understanding to get through most of the technical elements of the book. When I say “refurbishing” I mean “tinkering and occasionally get it to spring in to life”.

- My father was a mech engineer and had a connection with Ricardo, a British engineering research company which played a key role, and also with Vickers who bought Supermarine in 1928.

- This blog is essentially about the technical development of certain weapon technology – and this parallel weapon technology development to the matters I discuss on this site was pretty important.

- I “get” the importance of piston engine development at this period and had previously dipped into the subject a few years ago

- I know many of the readers of this blog have a broader technical interest in military history

Mr Douglas has written a tour de force here. The research from various sources in various languages has clearly been thorough and detailed. The book hangs together well, is well structured, laid out and with significant effort on technical images, which genuinely add to understanding. I admit that sometimes the replicated graphs of WW2 engine performance under tests sometimes become hard for me to decipher – a reflection on my patience rather than the author’s work. But they are there if you need to interpret them. He has bridged the highly technical subject matter to most readers with a modicum of knowledge like myself in a clear and unambiguous way. I confess at points I went off to do some side research in occasional subjects (like getting a better understanding of sleeve valves and disc valves, as an example, about which I was ignorant) to give me a better understanding of some of the issues he discusses but I don’t see this as a negative – I’m now a more knowledgeable reader. A book that encourages one to read more around a subject can only be a good thing. If the author had felt the need to explain such matters, it would be several volumes long and I think he chose the right path, by and large. Another example of this – I had to read up on the differences between “pre-ignition” and “detonation” (in terms of internal combustion engines) which I didn’t grasp the reasons for and the differences, but more importantly I was keen to understand the chemistry of detonation in the context my own separate understanding of explosive science. It surprised me that post-combustion products or remnants could explode “again” at the pressures present in the cylinder. Again, no huge negative and a detailed technical analysis like this would normally demand some contextual reading for the average consumer. I also like the way he gives detailed technical excerpts from his sources as part of the main narrative – it helps the book hang together rather than having to refer to appendices or footnotes. The verbatim arguments recorded diligently by stenographers between the various German protagonists is astounding and, separately, pithy letters within other nations equally surprises, and it’s a positive to detail these directly. On occasion a throw away line intrigues me and sets me off on a tangent – like the mention of 146 Merlin engines sat in France in June 1940 ahead of the Nazi invasion and an oblique mention of attempts’ to re-patriate them – there’s a story there, I suspect, that I’ll dig in to – readers may recall that I’ve written in the past about the efforts of The Earl of Suffolk who was getting machine tools, diamonds , scientists and heavy water out of France at this very time.

I think the book is important for a number of reasons:

- The development of aero engines in the 1930s shows how nation states can influence strategic technology development in both useful and negative ways. It is clear that the governments of UK, USA and Germany were all talking with commercial companies to develop key technologies, set priorities, targets, directions and aspirations, and providing money too. Sometimes that guidance failed or pushed matters in the wrong direction but at other times it led to remarkably fast technology development. Like many I had heard of the importance of the UK ‘s efforts to win the Schneider trophy in the early 1930s, and I had the false (schoolboy) impression that it was simply a precursor to the Spitfire, but only now do I see the the importance that this government funded effort to support the Supermarine company in the competition and the benefits in terms of engine development capability. But beyond that, the “R” engine in the Schneider trophy winning aircraft was hand-built and had an expected life of 4 hours operating only at sea level. In 1940, the RAF needed thousands of Merlin engines, with hundreds of hours possible on each, operating higher than 30,000ft.

- The pace of technology development was remarkable. We think that technology development is fast today in the early 21st century. But take this as an example – In 1914 many aircraft engines used a wick to deliver fuel to the combustion chamber. Just 17 years later, the “R” engine in the Supermarine S6 was as if from another planet, generating 2000bhp. But the “R” in the float plane only operated at sea-level. 12 years later Spitfire IXs were operating at 38,000 ft, an entirely different proposition

- It may seem that “piston engine development” is a single subject – but as Mr Douglas lays out, it’s much more interesting than that. To develop an aircraft piston engine the following technologies need to be improved, each of which impacts on and complicates the other:

- Engine layout and construction

- Metallurgy, as applied to every component

- Valve technology

- Fuel technology to prevent “knocking” or pre-detonation. Germany was hampered by the logistics of its synthetic fuel production.

- Carburation- how to get the fuel to the right place in the right form and with the right energy output – using carburettors, pressurised carburettors and eventually fuel injection. Hugely complex engineering challenges in this alone.

- Cooling technology and the associated challenges with pressurising cooling systems, applied to engines and components such as turbo chargers and even valves. I had no idea that liquid sodium was used as a coolant inside valves.

- Superchargers and Turbochargers.

- Lubrication technology

- Bearing technology

- Spark plug technology

- Logistics – the Luftwaffe were clearly hampered by poorly thought through logistics for their fuel production, by circumstance already a difficult challenge but one they made worse by poor decisions on storage and production logistics. This is in marked contrast to the British effort to secure a robust logistics system for 100 octane fuel.

- In some German engines the whole engine had to allow a gun barrel to be slid down the middle

The development of one technology often impacts on others – creating complexity. To give a simple example, adding lead to a fuel to improve its performance, has a knock-on effect (pun) causing more corrosion. So then a designer has to balance more performance with less engine life, along with a host of other implications from maintenance engineering resources, raw material supply, pilot training, production engineering, etc. At speed, in war and with life and death to consider too. It’s interesting that it often appeared that German research efforts were focused on “getting around” material constraints, while UK and US efforts largely focused on simple engine improvement. One wonders what the excellent German engineers could have done if resources were not a problem. Perhaps the Saturn 5 in the US space program indicates the potential of what might have been.

So the book is essentially a description of how nations pull together widely divergent technologies into a single strategic direction, with varying degrees of success. (Spoiler, the Allies win, although they were losing for some time). The author’s efforts to address the parallel tracks of technology development in a coherent way are commendable. I find it fascinating that each nation had its strengths within the above subsets of expertise but the overall successful engine required a fusion of many and, as often as not, that fusion was administrative rather than technical. In the early part of the war the German fuel injection system was streets ahead of problematic British carburettors. The Americans were better at fuel technology and turbochargers and the British had their strengths too, radiators being one example. Running successful engineering projects requires excellent communication systems and administrative skills as well as engineering knowledge. The question is, do those communication and administrative skills lie best in government or in engineering companies? In the German system at one stage there was a clear gap between a central ministry and the development labs in terms of setting technical priorities. It was a fault at this interface that caused the Me 109G , intended to be a replacement for the Me 1o9 F, to be no better than the aircraft it replaced – a true disaster from the German perspective. One particularly interesting example of British government-company integration was the installation of “moles” who were “embedded” with engine manufactures with a specific, openly acknowledged role of reporting to Beaverbrook’s Ministry of Aircraft Production (MAP), providing eyes and ears and direct up-to-date communications between Ministry and manufacturer. These liaison positions were titled “Resident Officers”. I think that’s an interesting concept. High tech development of multiple systems becomes a communications problem as much as anything else.

Government competence is an issue in terms of technical development. While there were some remarkably capable engineers within Nazi Germany, when the Nazis placed political appointees in the engineering system, or gave authority to people because they were famous pilots, things fell down. Fascists and competent government don’t go hand in hand. A good example is the appointment of Ernst Udet, a WW1 fighter pilot and protege of Goering to head a technical research department, for which he was eminently unsuitable. Running research departments demands an unusual fusion of technical brilliance and administrative skills – a mix that political extremists rarely provide. But in Germany it wasn’t just personal inadequacies that flawed their strategic engineering development response – it was also the structure and attitude of its fascist government that seemed to think that metaphorically barking orders equates to authoritative competence. Italy was even worse. That’s an interesting lesson for today’s governments too. Running trains on time might be within the capability of a fascist government, but not making a 2000bhp Merlin operate at 35,000 ft and shoe-horn it in to a Mustang. The point is really knocked home in reports in the book detailing how so many of the best Luftwaffe pilots were killed not by enemy action but by engine failure.

The book does highlight for me the strategic importance of any nation holding its engineers in high regard. The engineering talent that was applied to the development of piston engines in the 1930s and in subsequent war years is simply stunning. We celebrate the contribution soldiers and airmen make but the contribution to a national goal in war of engineers was never more apparent then. There were many more British aircraft engineers than Barnes Wallis, and dare I say some of them at least of equal stature, but today largely forgotten. For what it is worth the Germans provide a fine example still to this day – “Dr-Ing” is still an honourable title in Germany – but in the UK engineers seem to be held in less high regard. The occasional inserts provided by the author on key engineers emphasise the human aspect of this technological battle.

The amount of Technical Intelligence going on in the 1930s and 1940s was a surprise to me. British and American engineers visited Nazi engine development sites until the late 1930s and vice versa. Indeed in some areas technology was exchanged – the FW-190’s superior performance was at least due in part to above-board transfer of technology in the 1930s. Regular engineers working for civilian companies were clearly reporting back to government authorities about what they saw and heard on foreign visits. There was also covert activity with , for example, two German spies visiting the US Government facility at Wright Field in such a manner that they were able to draw extensive diagrams of equipment and tooling. The different approaches to analysis of captured enemy equipment is also fascinating – do you bang out a quick report, or do you spend a year or two doing detailed analysis? If you classify it as “Secret” , is it usable information? If you are 3/4 of the way through the development of your own fuel injection system is it helpful; or a distraction, to have a report on the enemy’s system thrust under your nose, by an analyst who perhaps hasn’t seen your work? Age-old problems seen in stark outline here with the US, UK and Germany all taking different approaches to Tech Intelligence analysis.

One area that particularly caught my attention, perhaps unsurprisingly, was a specific Technical Intelligence effort to examine fuel systems from captured or shot-down German aircraft. At every such opportunity, samples were taken, analysed and correlated over time. This provide a remarkable database for Air Intelligence to examine. Furthermore they clearly and specifically engaged with the top fuel scientists in the country to draw inferences from changing fuel specifications – and whether these were driven by technology demands or forced by fuel supply and synthesis problems. A great example of how collecting mundane data consistently can allow very valuable insights into enemy technical and strategic capabilities. The author, quite rightly, describes the analysis provided as a result as “astounding” – a great lesson for modern military technical intelligence. On the flip side however, the British took an age to work out that the additional gas injection system they found on captured German aircraft was using Nitrous Oxide, despite knowing that the Germans referred to it as the “Ha-Ha” system. It never occurred to the Tech Int analysts or indeed the British combustion experts until much later.

One final Technical Intelligence matter – Open source – there is repeated reference to the important technical information on newly developed German engines by reading articles in magazines – the German seemed quite comfortable even as late as 1942 to announce aspects of their engineering developments in openly published magazines for enthusiasts. Similarly, in November 1941 American articles about new fighter aircraft engines were being openly published, and German Tech Int copied a diagram of a twin supercharged Merlin from “Flight” magazine. Who needs spies when the opposition makes public their secrets? That is, assuming people to bother to read the published material, which was not always the case.

As I read the book, I encountered several fascinating engineering problems and learned how different nations addressed them – fuel dissolving in lubricating oil on cylinder walls was one such issue for the Germans who ran their engines cooler, but not so for the Merlin which had a deliberately hotter running coolant system but that meant the fuel evaporated off from the hot lubricating oil. Thus the German lubricating oil became dilute and less effective, even though, in principle, a cooler engine was a better thing. Another interesting technical issues for Messerschmidt 109s was an engine malfunction caused by high performance synthetic fuel being stored in a flexible canvas rubber bag, which the fuel reacted with, reducing the fuel’s performance, polluting it, and damaging engines, reducing their life.

As someone with a modicum of metallurgical knowledge I was still surprised at the criticality of the lack of nickel for the German war machine. I hadn’t come across that before and the author’s explanation of the implications of essentially the German nation having no nickel in any of its components are stark. There’s probably an interesting story somewhere about how they obtained what nickel they had, mainly from Finland. High performance engines operate in and produce inside themselves demanding environments for steel, and nickel is crucial in making steel less reactive -and this lack of nickel leads, as the author makes clear, to a direct consequence of lower performance engines. Their aircraft had less performance because of a lack of nickel – a mundane alloy component in today’s world. Imagine being the Daimler Benz house metallurgist and being told to come up with a nickel steel alloy, but not use any nickel. At a crucial part of the war (1942) the conflicting demands on metallurgical resources means that key alloys were being taken away from aircraft production for use in flak guns. Again, a fascist diktat-run government couldn’t manage the implications of that.

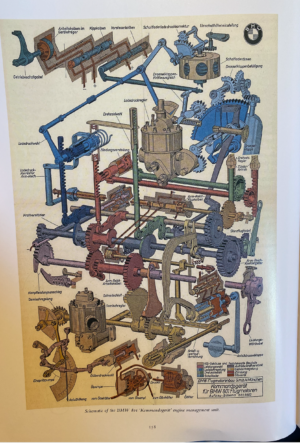

In one interesting area the German were well head and that was in developing control systems. The multiple subsystems in advanced piston engines create real challenges in terms of an operator managing them – and the Germans put great thought into automating these control systems where possible – allowing the pilots to concentrate on “being pilots” and not monitoring and adjusting sub-systems as a “flight engineer”. Today these would all be electronic but creating mechanical systems for this was quite something. Here’s an image below of the BMW engine management system from an Fw-190. Scarily complex, a mechanical analogue computer, automating engine controls. Also… imagine being the engineering intelligence analyst presented with a captured engine trying to work out what every component actually did – intelligence analysts need to be very competent engineers too, and that crosses over into my own field of expertise too:

In a time of current “National Crisis”, it’s interesting to sense the concern across the Allies in June 1942, as they examined a captured FW-190 and it became apparent they were “losing” the air battles with it, and why. The reports seem to reflect depression and deep concern that Allied aircraft improvements were some way off. Intriguing, especially since the Mk9 Spitfire was only a month away, and the P51 Mustang , also Merlin powered, arrived very soon after. It is also of interest that efforts to develop aircraft engines were in a sense similar to today’s efforts to make a Covid vaccine. You didn’t put all you eggs in one basket and in parallel with the continual (and amazing) development of the Merlin, several other horses/engines were backed, some of which proved fruitless, but in time of war made sense to reduce risk.

I also find it fascinating that piston engines of the time struggled to have a used duty cycle of hours flown – struggling often to get 100 hours without major refurbishment. I don’t know what they cycle is modern passenger jet aircraft power units is (fundamentally simpler, in a sense I guess), but the engine life must be in the ten thousands of hours. Another area that intrigued me was the development of turbine blade technology for turbochargers, and a very clever rim mounted turbine used in a Russian swirl throttle – I wonder if the science used in developing these was later applied to jet turbine blade design. Until now I had sort of assumed that turbine blade design for jets started from scratch.

It’s not my habit to pick out errors so hopefully the author will forgive my wry smile when Eric “Winkle” Brown is described as an RAF test pilot. He was of course, a naval officer, posted to the Royal Aircraft Establishment (RAE) as Chief Naval Test Pilot. Probably a simple transposition of an F for an E. My only other criticism , (I hope constructive) is that it would perhaps benefit from an Annex discussing the aircraft these engines provided power for – and their roles, as context for the engine development. It would have helped to understands that the Typhoon for instance originally was intended as a straight replacement for the Hurricane as an interceptor, and not as the “FGA” aircraft it became. Similarly the impact of the various models/roles versus engine variants of the Mosquito and Spitfire perhaps could have been pulled through a little more in an Annex.

Mr Douglas’s book brings a huge range of history and technical issues together in a readable and fascinating book. I’ve not some across a more enthralling book on an engineering subject. I’d recommend it to anyone with at least a little engineering knowledge. It’s well researched history, telling an important tale. You can get it online, but best of all use a local independent bookshop if you can. If you have a little engineering background and an interest in history, you’ll find this book fascinating.

Lastly an aside, which again brings about the human nature of war. On of the key Luftwaffe technical administrators was Field Marshall Erhard Milch – a fundamental protagonist in the competitive development of fighter engines. At the end of the war he tried to flee Germany but was caught on the Baltic Coast on 4th May 1945. On surrendering, he grandly attempted to surrender to British Brigadier Derek Mills-Roberts, a commando, while offering champagne, in an attempt to be treated kindly, according to his rank. Mills-Roberts was unimpressed with Milch’s attempted self-grandeur and attitude. In previous weeks he had been appalled by Nazi atrocities when he liberated Bergen-Belsen. He lost his temper, seized Milch’s Field-Marshall’s baton and broke it on Milch’s head and then beat him further with the champagne bottle, fracturing Milch’s skull. He kept the baton as a souvenir. Milch kept his skull, just.

May be interesting

http://samlib.ru/p/polo_m/tenizaekranom.shtml

Text (in russian, but GoogleTranslate can help) about battle for England, role of fuel additive (part 4 “hydrocarbon”) and chemist Vladimir Ipatieff.

https://marco—-polo.livejournal.com/ – autor (Sergey E.) blog

great review