I’ve written before about the evolution of gunlocks, from matchlocks, through wheel-locks to snap-huances and then flintlocks because although these initiation systems were designed to initiate firearms they also enabled initiation mechanisms for explosive devices. This post returns to that subject to discuss a couple of more elements to that story that I find interesting, namely engineering development and some fundamental issues about “energy” chains that apply both to these firearms systems and explosive devices. In this post I have made some generalisations and simplifications in my description of the technology – forgive me, but otherwise the post turns into a book and neither you or I have time for that.

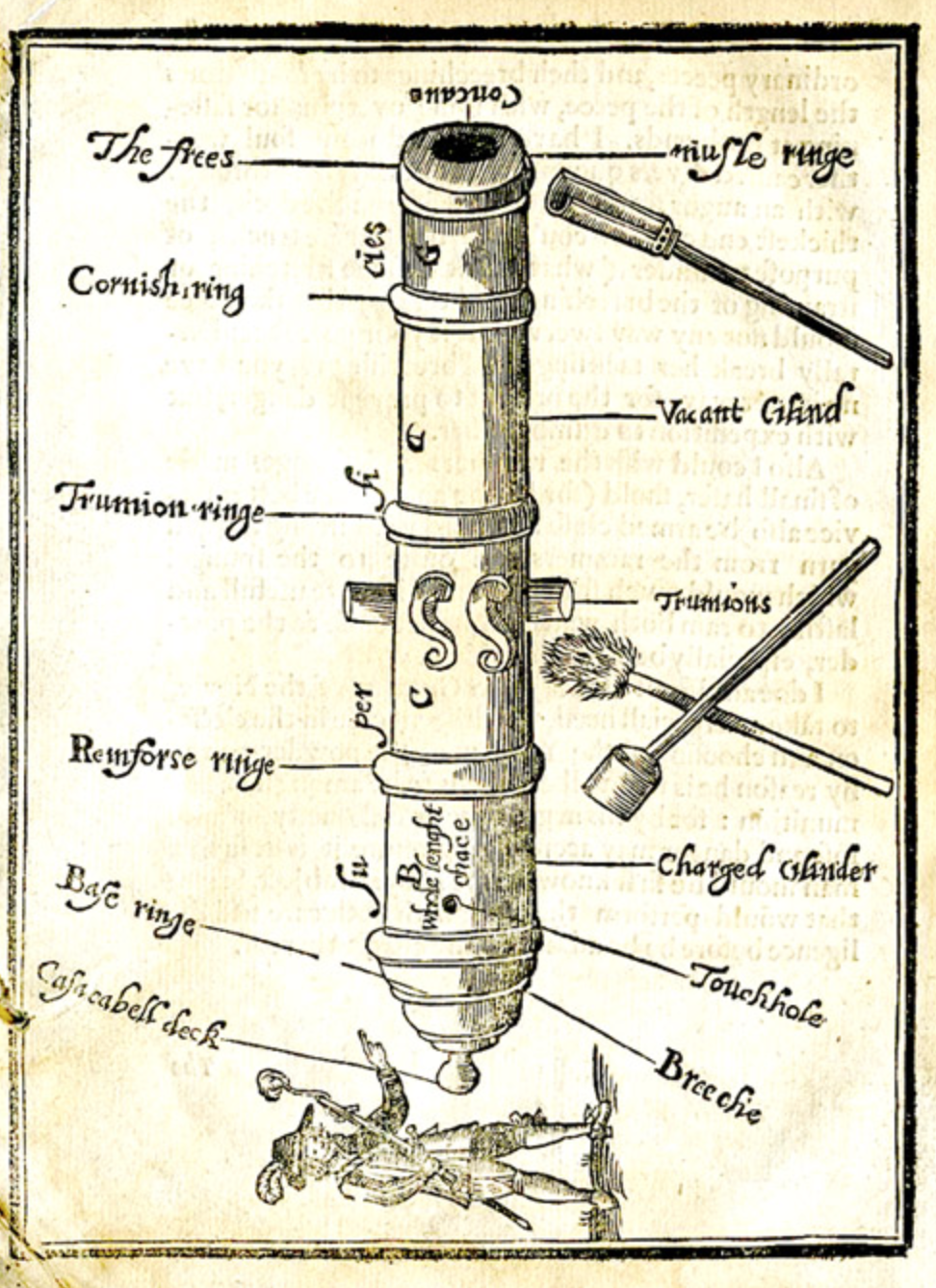

Firearm initiation systems, and in parallel explosive initiation systems, are about initiating a quantity of explosives at a time that the operator chooses. Thus, in the simplest of all firearm systems, a burning “match” is placed in contact with a small quantity of blackpowder in a “touch-hole” which then initiates a larger amount of blackpowder in the barrel of a gun. This system worked for hundreds of years in the cannons you see fired in all the movies.

The gun is aimed and the application of the burning “fuse” simply initiates the blackpowder. The energy in the arm of the man holding the fuse, and the energy in the already burning fuse is enough to initiate the stored chemical energy in the blackpowder in the barrel.

But in a small firearm there’s an issue of the man pointing the gun and initiating it at the same time. Generally these firearms were pretty large and required two hands to point at a target. So quite often the firearm was supported with a crutch allowing the firer to point it with one hand, sight the barrel with an eye at a target and use the “spare hand” to place the burning fuse on the touch hole.

Firing an early firearm without a trigger and serpentine

But let’s face it, that’s a bit fiddly. The touch hole is small and it might be a bit awkward. The firer is concentrating on doing two things, keeping the target in line and finding a small hole with the burning fuse in one hand. So, with some very simple engineering the matchlock was developed. All that happened was that a simple S shaped lever was introduced onto the body of the firearm. One end of the lever held the burning fuse in a specific position, the centre of the “s” shaped piece of metal was a pivot joint and the bottom end of the s was pulled with one finger. The placement of the s shaped lever (a “serpentine) ensured that the burning match always found the touchhole or the pan at the entrance to the touch hole, and the firer could use two hands to aim the firearm, concentrate on the target and just use a finger to pull the “s” shaped piece of metal.

A very early, simple matchlock arquebus

A very early, simple matchlock arquebus

Now , manufacturing such a firearm was pretty simple, and within the engineering skills of the average door-lock manufacturer of the 15th century which simply used levers and pivots. So matchlock firearms were relatively easy to manufacture and relatively cheap. Matchlocks continued to be produced from the 1400s for about 250 years. I think this is important to understand – although better technology was invented in a series, starting in the early 1500s, match-locks remained a simple and cheap firearm and so were the most common at least until well in to the 1600s.

A nice image of a Japanese matchlock mechanism showing a pan cover

Now, there are some operational weaknesses with the simple matchlocks. In the simplest of all matchlocks the pan or the entrance to the touchhole is permanently exposed to the elements. So in poor weather the firearm simply won’t work. Also the glowing match gives away both the position of the firer and the nature of their weapon. Both these weaknesses were partially addressed. Firstly a mechanism of a sliding or levered cover to the Pan or the entrance to the touchhole was developed, requiring some more intricate engineering so when the serpentine was moved then a cover was moved out of the way allowing the match access to the pan. A bit complex. Some attempts, too, were made to hide the burning match in a box, but not very effectively. Burning fuse also, by the way, made the weapon unsuitable for those guarding stores of ammunition. So in the early 1500s the wheel-lock was developed.

In large part the wheel-lock invention was enabled by advances in engineering, and specifically advances in engineering from clock making. On a fundamental level, the wheel-lock utilises, for the first time in a firearm, “potential energy” in a spring. A wheel-lock, consists of a steel wheel, which has a small chain wrapped around its axle. The wheel is rotated with a spanner, this wraps the chain around the axle and the other end of the chain is attached to a spring. Thus when the wheel is rotated it induces a potential energy into the spring. The spring is then held by a trigger. A second spring is then set up to hold the serpentine. In this case the serpentine doesn’t hold a burning fuse, but a small lump of iron pyrites. The spring acting on the serpentine holds the pyrites in contact with the rim of the steel wheel which usually has grooves on its circumference and some small notches to encourage friction. When the main spring holding the chain attached to the wheel is released by pulling the trigger, the steel wheel rotates and, because it is in contact with the iron pyrites, sparks are formed. The sparks initiate blackpowder in the pan.

So we have the potential energy in the spring, making kinetic energy in the wheel , which initiates chemical energy in contact with the pyrites, which initiates the chemical energy in the blackpowder, which converts to kinetic energy in the projectile, and that kinetic energy is transfered t o the target t cause damage. A nice little chain, but one which requires a significantly more detailed engineering capability than a match-lock.

The wheel-lock however has several advantages. It is safer, in that safety catches can be applied to both the serpentine and the wheel. The presence of a firearm is not given away by the burning fuse. It can be prepared well in advance of use (if the springs don’t deform as some where liable to) The firearm can be concealed. Since it is possible to conceal, the firearm was then made smaller, and so the pistol appeared for the first time, able to be held about a person, and the same person could indeed carry two or three wheel lock pistols. Since this is a blog about explosive devices, then of course the wheel-lock became a potential initiator for IEDs – the device could be hidden and initiated at a point of the firers choosing, perhaps say with a string to the trigger or a potential booby trap switch. IEDs are more suited to initiation by potential energy.

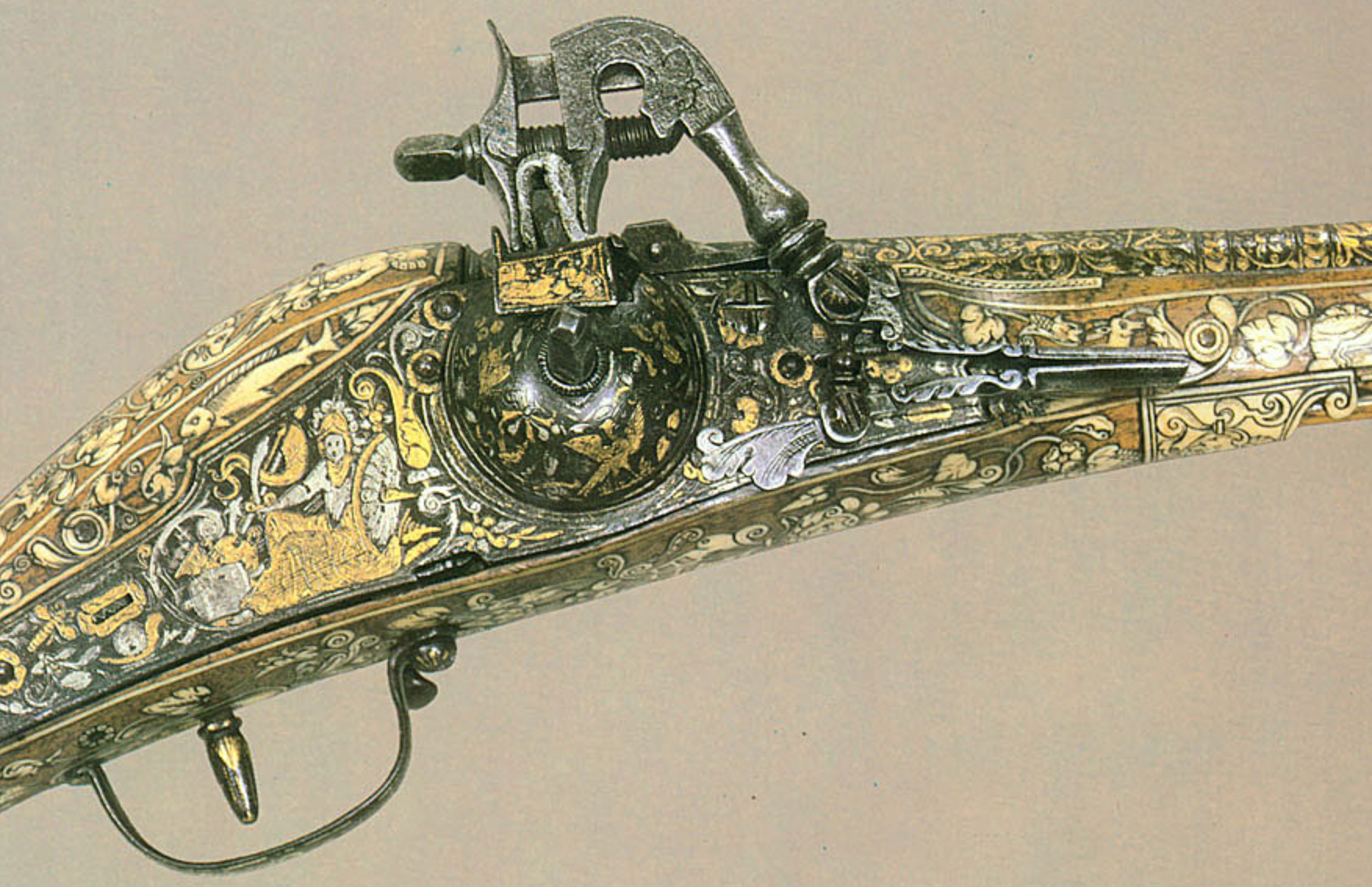

But now we have economics at play. The high level of engineering and therefore cost required for a wheel-lock would make it usually unsuitable for a one-time-use in an IED, although possible. Only the rich could afford wheel-locks. So wheel-locks and match-locks existed side by side for decades and indeed for at least 150 years. The economics of the engineering had some other interesting implications. Matchlocks are simple utilitarian devices usually without decoration through the 16th century. Wheel-locks however, bought by the rich became covered in ornate art, and became models of fine engineering and artistic excellence. Here’s some images of highly decorative wheel locks.

The fact that wheel-locks were used by the rich also had an effect on the manner in which warfare was conducted. Ordinary infantrymen could not afford wheel-locks but the aristocratic and rich cavalry could. Cavalry tactics then evolved to make benefit of the capabilities that two or three wheel locks could provide. The cavalry galloped forward to a point within range of their wheel-locks, fired, and galloped back. The tactics of cavalry using wheel-locks then had an impact on the types of horses and armour being used by the military. The huge horses required for armour encumbered cavalry with lances were replaced with smaller, quicker more agile horses. This perhaps lead, by connection, to the evolution of horse racing and blood stock management. The armour, designed to to defeat the weapons of the medieval horseman was discarded – armour could be produced to protect against the bullets fired from wheel-locks but frankly it was too heavy. So the nature of warfare rapidly evolved. One could say that the nature of warfare evolved over the period of between 1500 and 1620 entirely because of the initiation system moving to a potential energy storage device (a spring) for the initiator rather than a chemical energy storage initiator (the burning match).

Subsequent evolutions of the gun-lock technology brought together the principle of a potential energy store (from the springs in the wheel-lock), with simpler engineering requirements. I think that the spring-held serpentine of the wheel-lock got people thinking. Firstly pyrites wasn’t always a solid enough material to hold reliably in the jaws of the serpentine, and indeed the spring holding the pyrites wasn’t designed to cause the pyrites to impact with the steel wheel, just hold it against it. I think that the metallurgy of springs improved throughout out the 16th century. A powerful spring could cause a flint to strike a steel firmly and reliably enough to set a spark – earlier technology wouldn’t allow that – the springs would break or the springs would deform very quickly. But the evolution of clocks and associated engineering developed through the 16th century so that steel suitable for using in springs evolved. All of a sudden there was a metal available that could be used in a spring that could force a serpentine holding a flint hard enough to cause sparks. The “snaplock” then developed in about 1540 utilised the same serpentine used in the match-lock and wheel-lock, but this time powered by a strong spring to strike a “steel” to cause sparks – subsequent developments of the snap-huance and then the flintlock were simply improvements on that design, improving its reliability and weather protection. Essentially then in energy terms, the potential energy inherent in the spring that powered the wheel in the wheel-lock was changed to potential energy in the main-spring of the flintlock. Crucially though the engineering required of the flintlock was still considerably simpler than the technology used in the wheel-lock. Flintlocks could be pretty much mass produced while wheel-locks remained the product of a highly skilled craftsmen. As an aside, the engineering tolerances required of the wheel of the wheel-lock needed to be much tighter than the engineering tolerances in a flintlock. In a wheel-lock the wheel rotates through a slot in the “pan” and if the slot is too big then the gunpowder falls through it. The fact that flintlocks used potential energy , but were also cheap and able to be mass produced means that they became attractive to use in “one time use” IEDs such as this device . The first mine , Samual Zimmerman’s “fladdermine” also use a flintlock mechanism.

It is clear from reading up about the history of clock development that many of the principles of engineering in clocks developed during the period of about 1550 – 1750 were subsequently applied to the production of munitions fuses. There’s probably another blog (or book!) to be written about that.

Roger Davies

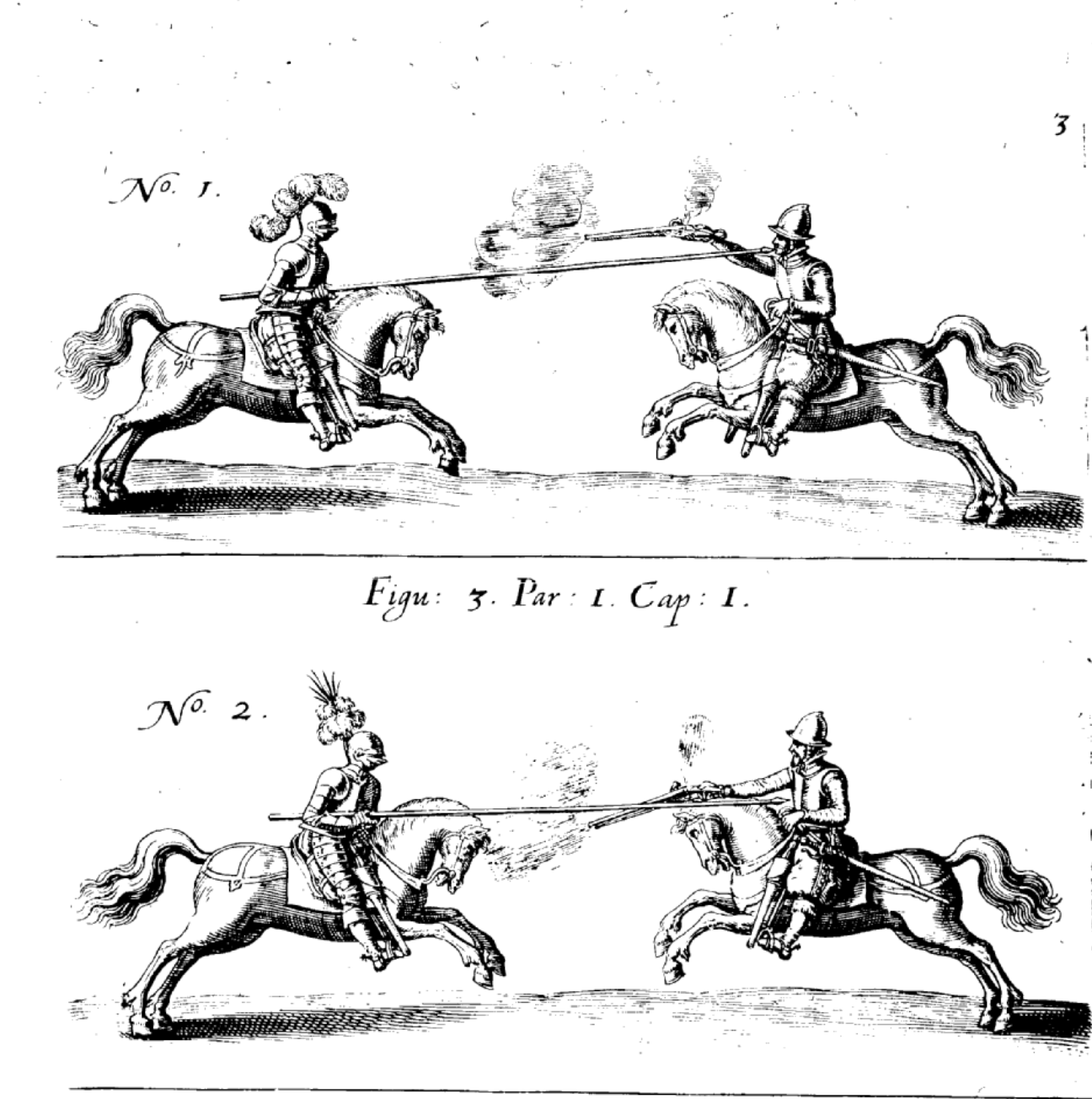

Roger DaviesAs a follow up I found this excellent image from a French military handbook published in 1616, showing how a small one handed wheel-lock pistol could be used by a “new” cavalryman against a “traditional” knight in armour with a lance. Step one, shoot the knight from beyond the range of his weapon, or alternatively, step 2, shoot his horse. Note the difference in armour of both protagonist.